UPHOLSTERY

Brief History of Keystone Upholstering Company

Keystone Upholstering Company was founded by Raymond D. Marzani, a lifelong resident of the Tripps Park section of Scranton. Born in 1931 at the historic Tripp House into a family of tailors, Ray took naturally to the upholstering trade. He honed his skills under the tutelage of Mr. William Gressler, a German-born upholsterer who had immigrated to the area following the Depression.

After outgrowing several buildings in North Scranton, Mr. Marzani bought the large 3-story building on North Main Avenue which continues to house the business to this day. Keystone Upholstering was officially established in 1963 on the third floor, and the building’s prime location in North Scranton attracted many other businesses to the first and second floors, including a dress factory, machine shop, and home improvement store. These businesses employed dozens of residents and played an important part in Scranton’s economic development over the past 50 years.

From its founding, Keystone Upholstering Company has been known for quality craftsmanship in all styles of furniture upholstering. With a reputation for prompt, courteous service and fair pricing, Keystone Upholstering Company has been and continues to be the most trusted and utilized shop in the Northeast Pennsylvania region. Commercial or residential, Keystone Upholstering Company is proud to lend its expertise to any project serving the needs of the community.

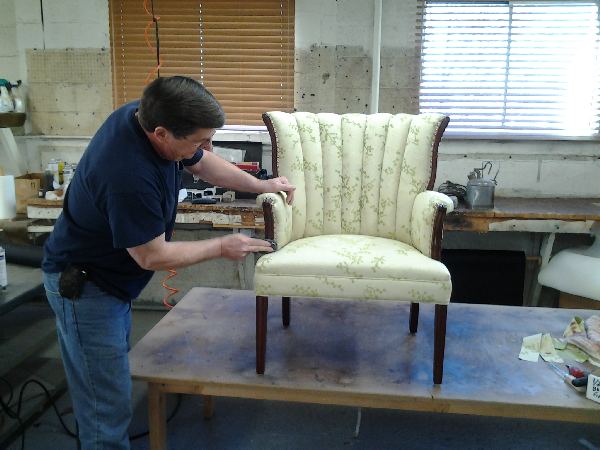

Keystone Upholstering Company is now operated by Mr. Marzani’s sons Matt and Ray, and grandson Nate. Having worked in the business all their lives, Matt and Ray are master craftsmen with expertise in method and technique even beyond their father.

Welcoming large as well as small jobs, the team is adept at all aspects of upholstering, transforming furniture in the most impossible state of disrepair into beautiful, comfortable and durable pieces that will enhance any setting.

They also specialize in creating custom pieces such as ottomans, headboards, and cushions for built-ins. With their extraordinary work ethic and personable natures, Matt, Ray and Nate carry on the Marzani customer-oriented tradition while still offering only the highest quality upholstering service.

Should you reupholster your furniture?

Reasons to Reupholster

-

You’d like to maintain the shape and style of the furniture

-

The furniture fits your room just right

-

The furniture has sentimental value to you

-

The furniture is old, and therefore, well-made

-

You can’t find any newly manufactured pieces that you like as much

-

You want to freshen up the look of an old piece with a new fabric

-

You want to alter the filling in the piece to make it more comfortable for your personal needs

-

You believe in supporting quality workmanship by local, independent craftsmen

-

You believe in “recycling” and reducing what goes into landfills

The Reupholstering Process

• All fabric and filling is stripped from the piece, down to the frame

• Frame is repaired and/or reglued if necessary

• Springs are retied, rewired, or replaced as needed

• Frame is touched up and polished

• Filling is replaced with high-density foam

• In the cases of down/kapok filling, it is sterilized and reused, if possible

• New fabric is applied to the furniture

• Cushions, skirts, pillows, and welts are sewn in by hand

• Detailing of the finished product

• Furniture is wrapped with plastic for protection and ready to go home!

*Pick-up and delivery is available if needed!

“Don’t worry about the current condition of your furniture when it comes to reupholstering! Keystone Upholstering can revive furniture that’s been neglected for years! Just take a look at the condition of these 2 chairs prior to reupholstering!”

Buy new or reupholster? Which is the better deal?

While new furniture can sometimes cost less than reupholstering, reupholstering can only be done by expert craftsmen and, unlike factory-manufactured furniture, utilizes high-quality materials to give you the best value for your dollar!

Even just 10 years ago, there were much higher standards of quality in furniture manufacturing compared to what is being constructed today

Although new pieces may seem less costly, manufacturers often cut production costs in the following ways, leading to poorer quality furniture not made to last:

-

Elimination of hardwood-based frames

-

Elimination of spring-systems for support

-

Utilization of low-grade cushion filling

-

Application of fabrics that lack durability

-

Use of overseas manufacturing plants

Pricing Expectations